· The Arm Team · 1 min read

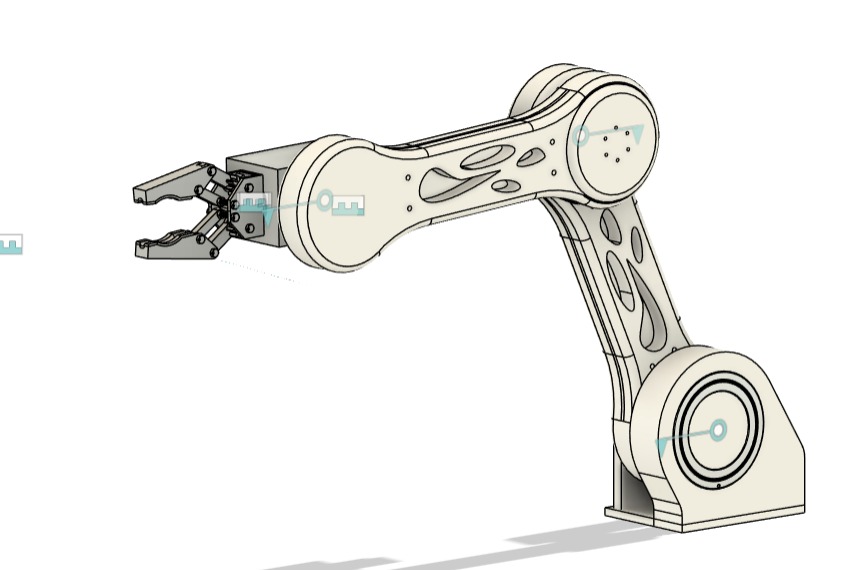

Our 6-DOF Rover Arm - Strength Meets Precision

Our new 6 Degrees of Freedom (6-DOF) robotic arm is designed for high performance and reliability. Built using a sandwich structure of 3D-printed parts and metal reinforcements, it combines low weight with excellent strength and rigidity.

Our new 6 Degrees of Freedom (6-DOF) robotic arm is designed for high performance and reliability. Built using a sandwich structure of 3D-printed parts and metal reinforcements, it combines low weight with excellent strength and rigidity.

Structure

The arm’s 3D-printed shells allow complex geometries and reduce mass, while metal inserts strengthen load-bearing areas. This hybrid design achieves the perfect balance between durability and manufacturability.

Actuation

Each joint uses a cycloidal gear drive, offering high torque, zero backlash, and smooth motion. This setup efficiently converts motor rotation into precise, amplified torque — ideal for stable operation even under varying loads.

Performance

With six rotational joints, the arm provides human-like motion and fine control. Its compact, modular design ensures easy integration on the rover and straightforward maintenance.

In Summary

By combining 3D printing, metal reinforcement, and cycloidal gear actuation, we’ve created a lightweight yet powerful 6-DOF arm — built for precision, strength, and reliable exploration.