· Dinesh, Lohitashwa · 2 min read

How We Plan To Do Power Distribution

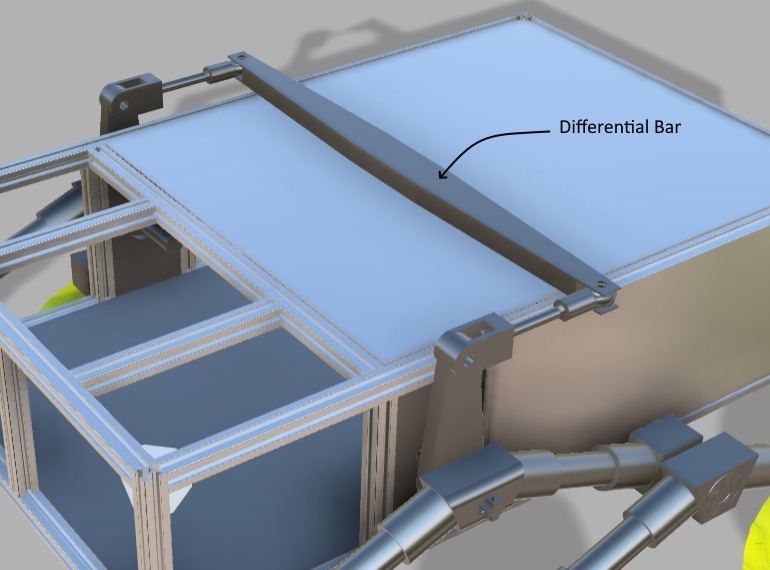

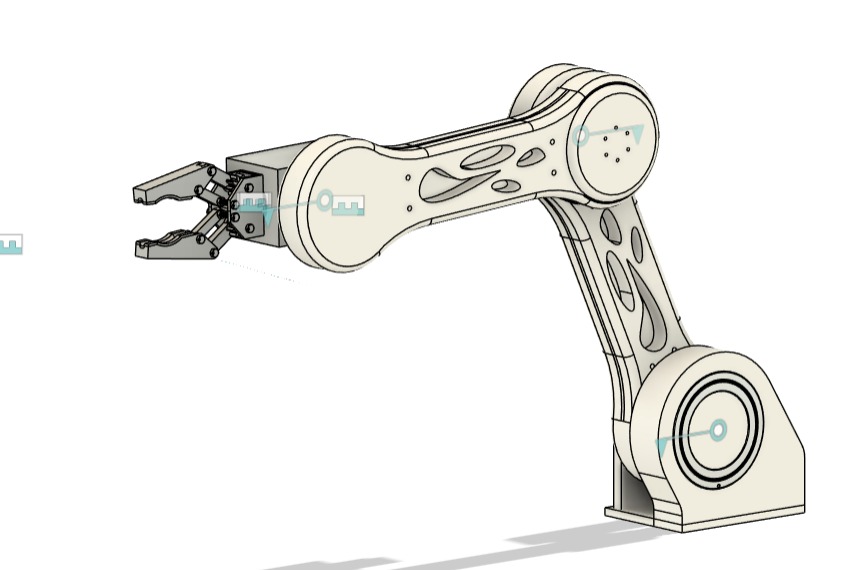

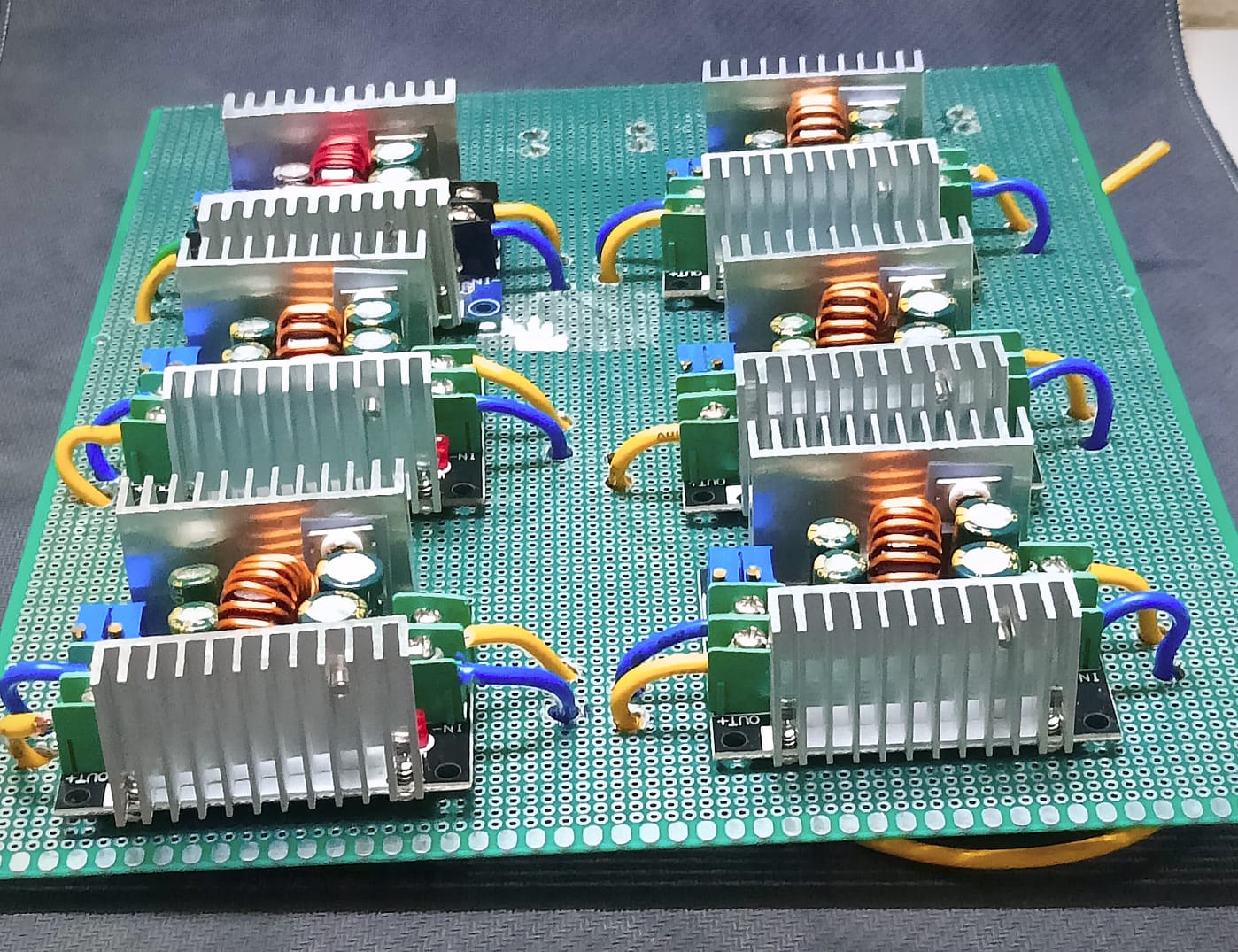

This advanced robotic system features a sophisticated two-tier power management architecture designed to efficiently distribute power from a 24V battery source to multiple subsystems. The design incorporates strategic buck converter placement to ensure optimal voltage regulation and independent control of various robotic components.

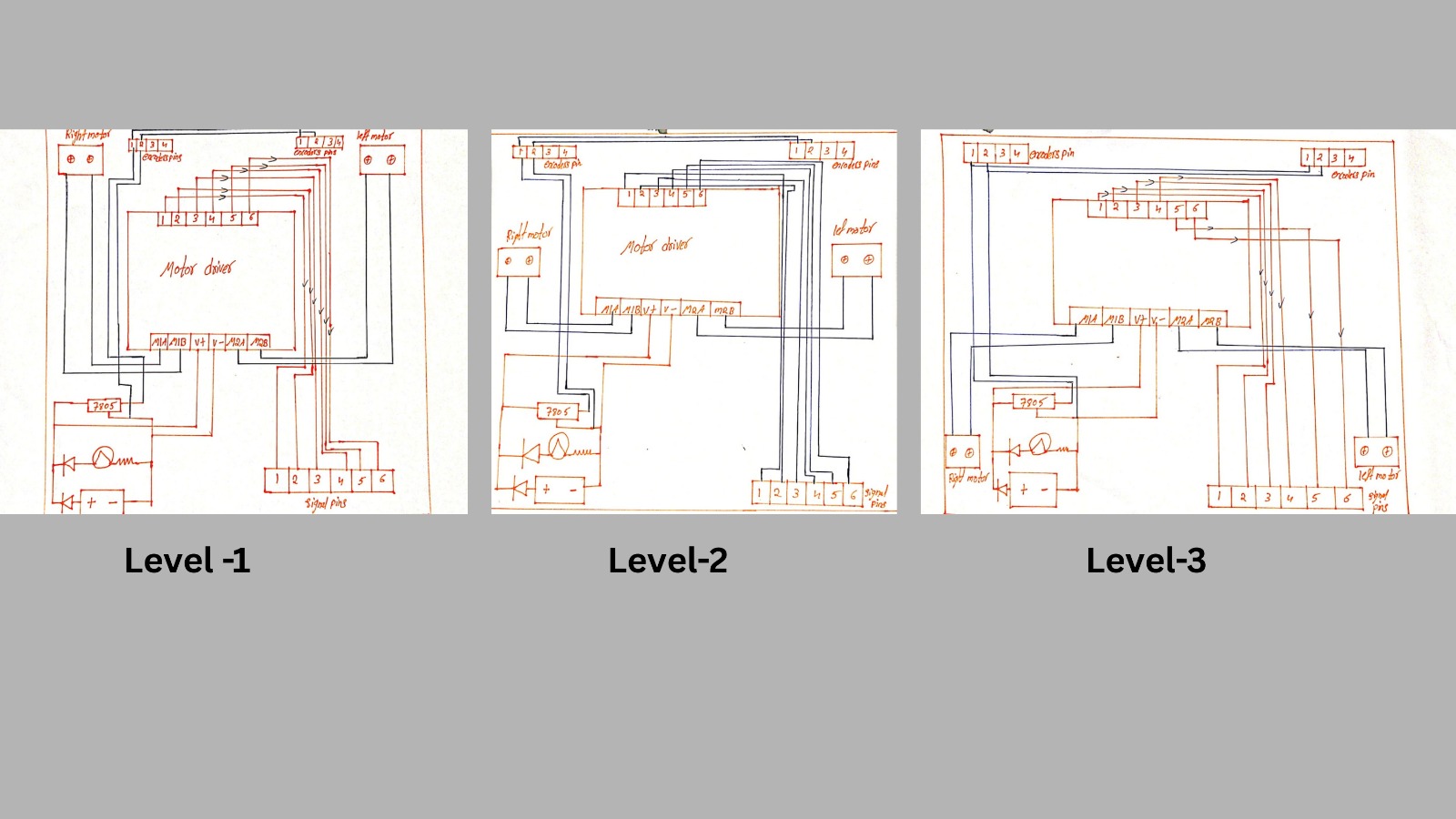

First-Level Power Distribution

The primary power distribution level consists of six dedicated buck converters, each equipped with individual toggle switches for independent activation and deactivation. This configuration provides granular control over power delivery to different subsystems:

Three buck converters are specifically allocated to chassis motors, providing the necessary power conversion for the robot’s primary locomotion system

Three additional buck converters serve the servo motors, enabling precise control of actuators and positioning mechanisms

Each first-level converter includes integrated toggle switch control, allowing operators to selectively enable or disable specific motor groups without affecting other subsystems.

Second-Level Power Distribution

The secondary distribution tier features four specialized buck converters housed on a dedicated PCB, designed for more sensitive electronic systems:

Two buck converters are dedicated to powering the robotic arm assembly, ensuring stable voltage supply for precision movement and control

Two converters support the science module operations, providing clean, regulated power for sensors and experimental equipment

System Architecture Benefits

This multi-tier approach offers several key advantages for robotic applications :

Independent subsystem control through individual switching mechanisms

Efficient power conversion from 24V battery to various voltage requirements

Modular design allowing for easy maintenance and upgrades

Fault isolation preventing single-point failures from affecting the entire system

Optimized power distribution matching each subsystem’s specific power requirements

The system’s hierarchical structure ensures reliable power delivery while maintaining the flexibility needed for complex robotic operations across multiple functional domains.